Generator and Controller products target prime mover OEM for electric vertical takeoff and landing (eVTOL) vehicles

GOLETA — LaunchPoint Electric Propulsion Solutions, Inc., an aerospace power generation and electric propulsion design company in Goleta, announced (on April 12) the commercialization of its patent-pending, hybrid electric power system for aircraft.

GOLETA — LaunchPoint Electric Propulsion Solutions, Inc., an aerospace power generation and electric propulsion design company in Goleta, announced (on April 12) the commercialization of its patent-pending, hybrid electric power system for aircraft.

The LaunchPoint™ Hybrid Power System (HPS) is a revolutionary ecosystem of complex motor and controller hardware, plus software for eVTOL aircraft of all types. The system increases flight performance beyond what battery-only or engine-only-powered flight can deliver. It uses a combination of an internal combustion engine and a battery electric distributed drive system for propulsion that increases system-specific power and decreases energy storage mass.

“Simply put, the LaunchPoint™ HPS is the brawn and brains of a power system of what would be characterized as the equivalent of a ‘flying Prius’ with cruise control – optimized for vehicle range, payload, flight/hover time and battery life,” said Rob Reali, LaunchPoint’s Chief Executive Officer. “Our novel arrangements of component features and innovations meet the needs of the emerging Advanced Air Mobility (AAM) market.”

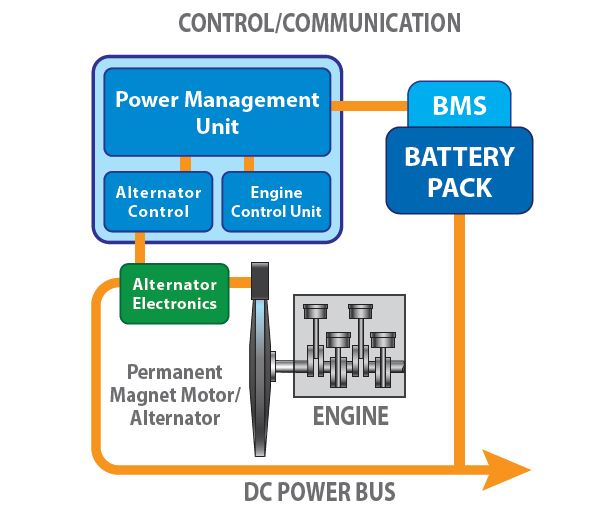

The HPS product family consists of electric motors, generators, drives, controllers, and hybrid electric power management units (PMU) designed for power generation and fully electric and hybrid electric propulsion applications. The system is designed to support both Parallel and Series hybrid operations.

“We’ve evolved the HPS over twelve years to meet the complexities of demanding flight and safety requirements for AAM and unmanned aerial systems (UAS),” said LaunchPoint’s Chief Technology Officer, Mike Ricci. “The integrated electromechanical system utilizes our proprietary SmartPoint™ control software to coordinate complex, dynamic hardware components, including the engines/prime movers, and intelligently respond to a wide range of system requirements in real time. The system not only solves the problem of regulating variable voltage sources – such as PM generators and fuel cells – but it also works together as a microgrid power manager to optimally use energy resources on a vehicle. Power is rerouted to enable reliable, fault-tolerant flight. It is an excellent system for our customers that want to run generators and for those who are looking to develop power generation solutions based on LaunchPoint’s generators and controllers.”

LaunchPoint™ HPS products range from 1.5 kW to 40 kW to power UAS. Systems for passenger and large cargo air mobility applications are customized solutions in the 40 kW to 250 kW range, and higher. Customized solutions are all modeled using LaunchPoint’s Modeling Advanced Aircraft Propulsion (MAAP™) proprietary software suite, which optimizes how a powertrain or electrical power system is architected.

In addition, the company has made the individual parts of its Hybrid Power System available for licensing and OEM sales.

The Hybrid Power System consists of:

- Permanent magnet motor/alternator

- Customer specified engine/prime mover (ICEs, turbines, fuel cells, etc.)

- Customer specified battery pack

- Power Management Unit

- High Voltage Alternator Controller

- Battery Management System

Features:

- Microprocessor-based system with proprietary software that monitors all functions

- Power Management Capability

- Recharge: Enables in-flight recharging of battery pack

- Power: Manages combined battery/generator power on DC bus

- Monitor: a digital “fuel gauge” measures all cell voltages and temperatures and state of charge (SOC) measurement capability

- Fault Condition: Manages the integrated intelligence to disconnect faulted/failed subsystems from DC Bus in real time

- Battery Management: Processes sensor data to derive battery pack measurements

- Proprietary Control Modes

- Rotor sync capability between multiple motors/drives + rotor position control mode

- PWM frequencies >100 kHz Support

- Sensorless + once around and Hall sensor + once around control modes

- Engine/DC Bus Power Control

- Engine control interface via PWM or serial data link

- Choke control for starting

- Starter signal for external starter motor applications

- DC bus and logic power voltage sensing for flight instrumentation

- Comprehensive Onboard Diagnostics and Fault Detection + Reporting